Chronic Unresolved Problems

-

94%Percentage of projects that haveTime Over Run (TOR) as against Original Completion Schedule

-

84%Percentage of projects with Cost Over Run (COR) as against Initial Budget

Reason Behind Delays

Every successful project has a unique story. But, all failed projects share a common story.

Insight For Solution

When every stake holder is blaming someone else, it is a clear indication of failed collaboration.

Infrastucture projects are inevitably delayed

-

Project Manager

- Lot of expediting required across all departments

- Unreliable suppliers on commitments

Project Manager

- Lot of expediting required across

all departments - Unreliable suppliers on commitments

- PO placement was delayed

- Scope revisions after placing the order

- Delay in giving manufacturing clearance

-

Supplier

- PO placement was delayed

- Scope revisions after placing the order

- Delay in giving manufacturing clearance

Supplier

- PO placement was delayed

- Scope revisions after placing the order

- Delay in giving manufacturing clearance

- PO placement was delayed

- Scope revisions after placing the order

- Delay in giving manufacturing clearance

-

Contractor

- Drawings were not available in time

- Required material was not available

when needed

Contractor

- Drawings were not available in time

- Required material was not available

when needed - PO placement was delayed

- Scope revisions after placing the order

- Delay in giving manufacturing clearance

-

Designer

- Drawings were not available in time

- Required material was not available

when needed

Designer

- Drawings were not available in time

- Required material was not available

when needed - PO placement was delayed

- Scope revisions after placing the order

- Delay in giving manufacturing clearance

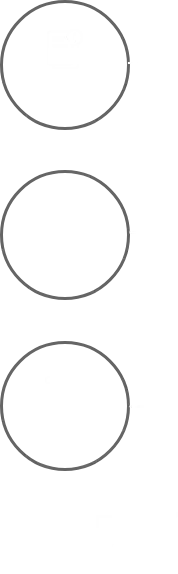

Total Execution Lead Time

If collaboration-led wastages can be plugged, time can be freed up to manage

unavoidable uncertainties.

The blame game is usually focussed around the inadequacy of

These give rise to 3-types of

collaboration-lead wastages

-

Interruptions

-

Slow Down

-

Rework

-

Touch Time

(Actual Work Time) - Avoidable Delays

- Unavoidable Uncertainty

Total Execution Lead Time

Total Execution Lead Time

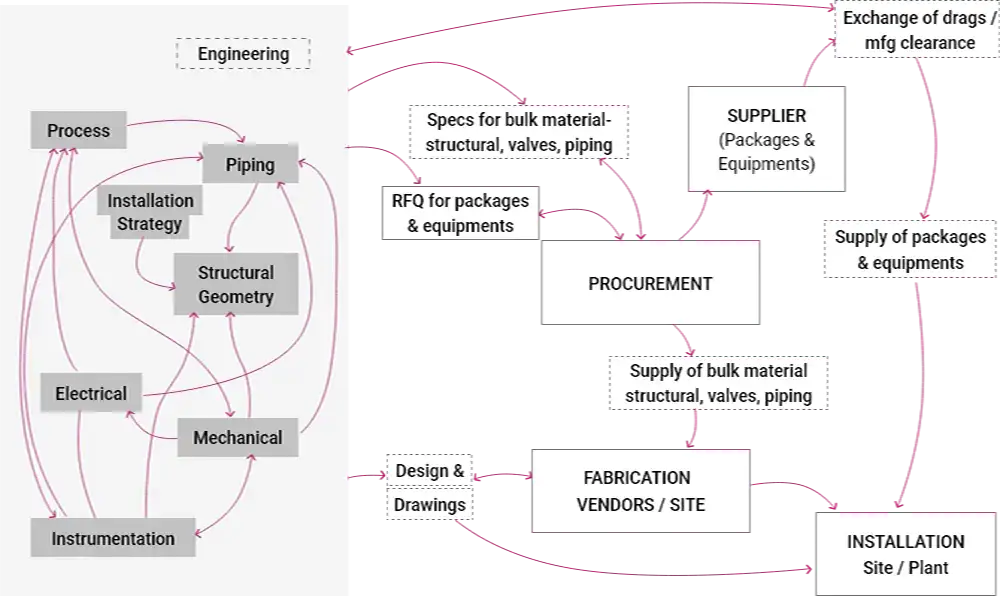

Obstacle For Collaboration

Collaboration can be complex when multiple parties are involved.

Solution that does not work

The current approach of seeking collaboration is through a practice of conditional commitment.

The more agencies involved and higher the uncertainty in the project, it is likely that at least one agency will fall behind its commitment. Thus, for effective collaboration, each agency must compensate for delays caused by other agencies. However, this rarely happens.

The traditional practice of conditional commitment comes in the way of effective collaboration.

-

I will give you the drawing on March 24th, only if I receive inputs by Feb 24th

-

I didn’t get drawing in time, hence I could not complete the excavation as per schedule

Vector Consulting’s ProjectFlow based approach for managing industrial CAPEX projects has helped companies break the conditional commitment syndrome and deliver projects on time.

To know more download the articleBajaj Electricals Engineering And Projects Division

- Engineering & Construction

- Rapid Projects Execution

With the new paradigm of synchronized supply and execution management, the company now delivers most projects 3-4 months early

Over the last 75 years, Bajaj Electricals Ltd, a pioneer in electrical home appliances, lighting and luminaires business, has progressively diversified into turnkey projects. Bajaj Illumination and High mast lighting system projects involve providing lighting solutions for a wide spectrum of utilities such as airports, shipyards, port trusts, sports stadiums, monuments etc., while the Power Distribution projects work on rural electrification. And TLT projects cater to connecting power transmission grids across India –i.e. connecting power generating plants or sub-stations.

Most of the EPC projects in India are executed in environments of high uncertainty; completion of these projects require coordination and cooperation between various stakeholders like state-owned companies, individual landowners and the contractors. Therefore, gross delays are very common. When Bajaj started TOC implementation, it too had large number of open projects with chronic delays and cost over runs but with the new paradigm of TOC based synchronized supply and execution management of projects, the company reaped both operational and financial benefits. The results include:

Client Speaks

We embarked on the journey of implementing TOC processes along with Vector Consulting Group, to realize the full potential of all categories.

Anant Bajaj

Managing Director, Bajaj Electricals

Our primary sales had been growing at 20% a year. Most of the growth was from few products. Only a few SKUs had significant penetration among a large base of retailers. We embarked on the journey of implementing TOC processes along with our consulting partners, Vector Consulting Group, to realize the full potential of all categories.

After enabling the supply chain, we are in the process of rolling out this initiative pan-India. Currently, the initiative is in first phase of roll out in selected branches. The reach in these regions has doubled, retailers added 40% new SKUs. The secondary sales have gone up by more than 50%.

The implementation is a paradigm shift not only for us but also for distributors. Many age-old industry beliefs had to be challenged. For example, we had to move away from pushing for primary sales targets. At the same time, steps were taken to create price hygiene to avoid territorial conflict and to protect the interests of retailers. The distributor had to be convinced to deploy resources to improve range and reach. Many distributors cherry-picked outlets based on sales volume and payment realization comfort, all other outlets were termed bad counters. We had to break this myth of bad counter by ensuring retailers capital is not blocked and at the same time see that each retailer has a single source of supply. The process of supplying small lots frequently helped break the myth. We also changed our volume-based schemes. The results are exciting.

Video Case Study

Bajaj Electricals Ltd. : Turning Around The Engineering And Projects Business

In spite of a highly uncertain environment, Bajaj Electricals now not only delivers large projects faster but it has also done so while consistently improving financial results!

Godrej Power Infrastructure & Renewable Energy

- Engineering & Construction

- Rapid Projects Execution

The company adopted TOC method of planning and executing projects to consistently complete projects in time

Godrej PIRE (Power infrastructure & renewable energy business) is considered as a critical revenue driver for the Godrej & Boyce Group. But in 2013-14, the company was experiencing a common industry situation. The projects of the company (large scale village electrifications, electrical substations), were chronically delayed, thereby requiring more working capital to be ploughed in. Moreover, the company also had to contend with cost over runs and negative margins. Therefore with the objective of turning around the business by completing projects in time, Godrej PIRE adopted the TOC methodology. With thrust on erection billing vis-à-vis the erstwhile focus on supply billing, and increased focus on undertaking EHV projects (which offers higher margins), the company achieved following results:”

| Parameter | Improvement |

|---|---|

| Lead time | Reduced by 50% |

| Output | Increased by 130% |

| Working capital | Reduced by 20-25% |

| Working capital (days) | reduced by 47% |

| Inventory | Reduced by 25% |

Video Case Study

Godrej Electricals & Electronics : Rapid Execution Of Infrastructure Projects

Trident Group

- Engineering & Construction

- Rapid Projects Execution

Adopting TOC principles, the company erected a spinning plant of 30,000 spindles, in a record time of nine months

One of the leading players in textile industry, Abhishek Industries (Trident Group) erected a spinning plant of 30,000 spindles using CCPM. A greenfield project, it was completed in a record time of nine months as compared to the industry benchmark of 12 months. The ramp-up to peak production was also achieved in 40 days as compared to the typical industry time of 3-4 months.

Get in touch

Vector Management Consulting Pvt. Ltd.

10th floor, Thane One, DIL Complex,

Ghodbunder Road, Majiwada,

Thane (West), Maharashtra - 400610, India.