Textiles and Garments

Companies in this domain are export houses which undertake garment manufacturing for large retailers as per fabric or garment designs given to them. They could also be fashion retailers who design, source and sell garments under their own brands in addition to selling other garment company brands. These two types of companies (textile manufacturers or fashion garment retailers) can develop a constraint in Operations, Sales, Retail operations or in Sampling.

Operations

Our Offer

Around

50%

Reduction in overall lead-time

Upto

25%

Increase in output of textile manufacturing

Upto

40%

Reduction of WIP

Improvement in working capital cycle of the company

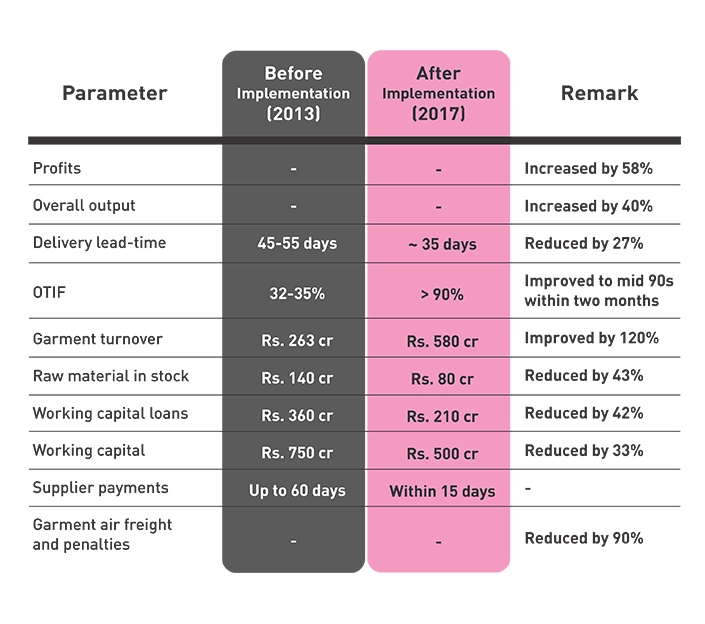

Most garment and textile manufacturers in India are facing severe pressure to reduce not just costs but also to reduce lead time of supply of garment orders. The pressure on costs is emanating from the gradual change in product mix of garment orders being received. Over time, garmenting orders have shifted from being for few garments in large volumes to a large variety of garments in smaller volumes. The pressure of lead times is emanating from retailers who want to reduce the fashion forecast horizon. The twin pressures of increased variety of garments and low lead times are making it necessary for textile and garmenting units to make fundamental changes in the way they operate. Most manufacturers are not coping well with these demands; they are suffering from drop in output, poor delivery performance, and month-end skew in output of garments. These issues are further driving up costs of garmenting and jeopardising future order bookings.

With the help of Vector Consulting, textile and garment manufacturing plants can ensure near ~100% On-Time-In-Full deliveries with significant reduction in lead time. At the same time, they can increase the garment output and significantly reduce working capital deployed in the business. Find out how.

Read More

Sales Bandwidth

Our Offer

More than

100%

Release capacity of sales team

Increase the rate of acquisition of new customers

Increase in sales rate of new garment categories

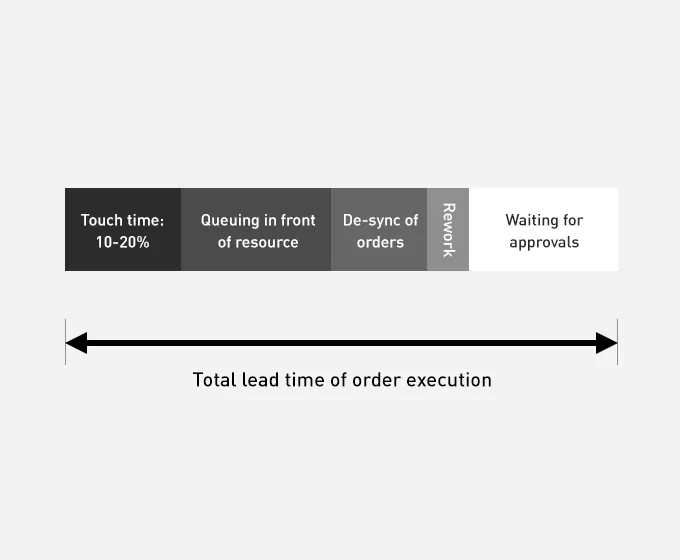

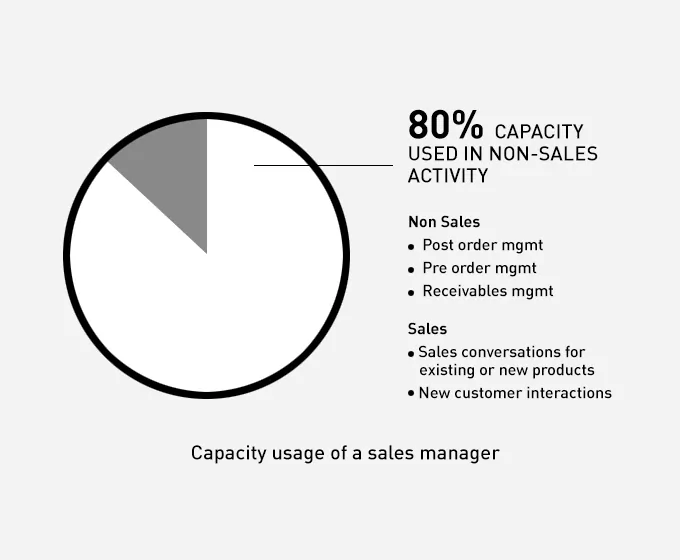

Significant time of sales teams in textile and garment manufacturing companies is used up in order management. When every garmenting order has multiple co-ordination points for approvals with clients, the sales team bandwidth is mostly occupied in short-term tasks required for execution of orders in hand. This consumes capacity that is needed to develop new customers or introduce new garment categories.

Textile and garment manufacturing companies can increase bandwidth and effectiveness of their sales teams, and, simultaneously, improve the service levels of orders on the shop floor. Know how this is possible with the help of Vector’s consulting expertise in this domain.

Read More

Retail Operations

Our Offer

Around

20%

Growth in same-store sales growth

More than

100%

Improve garment inventory

Increase gross contribution per unit of shelf space

Improve display and freshness of garments on shelf space

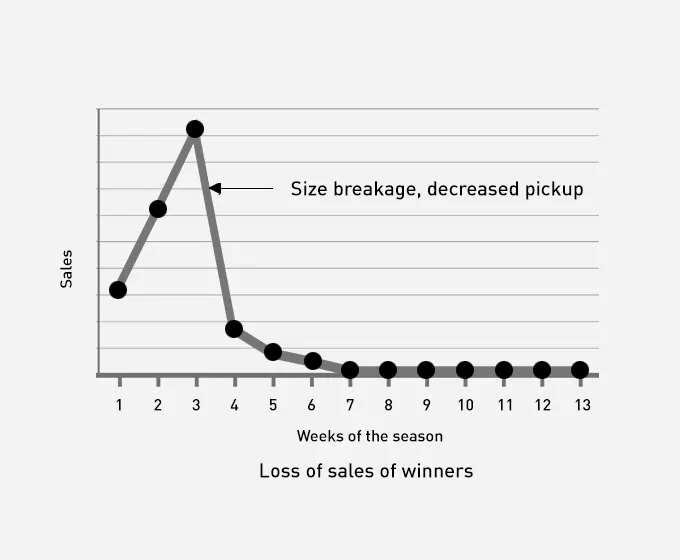

Fashion houses having their own retail footprint are typically constrained by store shelf-space (or working capital) for displaying garments. Slower the inventory ‘rotates’ on available shelf space, lesser is the money that the retail store makes. Fashion retail stores’ inability to fully exploit the limited shelf space in the store arises due to two reasons. Firstly, about 15 to 20% of the garments become bestsellers and gets stocked out within few weeks of season onset. Unfortunately, most fashion houses are not able to react to this by restocking (due to the long lead time needed for development and supply of garments). Secondly, about 30% of the garments turns out to be duds. When this happens, immediate effect is of blocked working capital. This also eventually causes margin erosion due to the inevitable deep discounting necessary to shed these excess garments.

How can fashion retail companies drastically reduce the impact of garment stockouts and surpluses, and at the same time, release working capital for funding expansion plans? Find out

Read More

Sampling

Our Offer

Upto

50%

Reduce garment sampling lead-time

Upto

50%

Increased Output resource base

Reduce rework

Improved quality of output

Rapid bulk garment production

Reduced stress on people and other resource

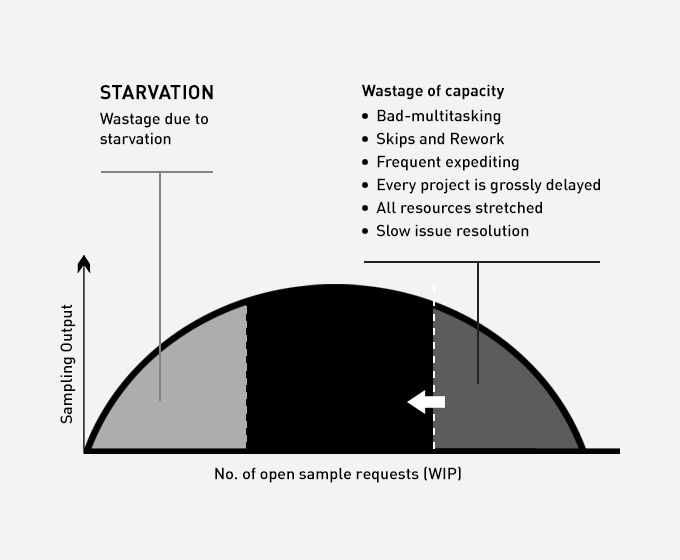

Once the supply chain is aligned for seamless flow of orders, the next level of constraint for any textile or garment manufacturing organization is its ability to offer new garment variety based on the latest trends of fashion. In order to do so, the company has to have an agile garment sampling process. However, lead time of garment sampling expands either due to queuing delays or priority conflicts with bulk garment production. Moreover, fabric and garment designers are also caught in priority conflicts as they try to fulfil requirements of multiple sales channels. Consequently, garment sampling process can be a major bottleneck for bringing in new customers and for converting enquiries into orders.

Using flow principles of TOC, textile manufacturing and garmenting companies can transform the sampling process to align it with the goal of timely completion of orders. This would also help the companies to release substantial capacity to do more (garment sampling) from same resources.

Read More

Case Studies

Discover how textile and garment manufacturing companies like Pratibha Syntex, Raymond Textiles, and many others are using “pull” systems of Theory of Constraints to dramatically reduce their ‘fabric to fashion’ lead time and gain a competitive advantage in the markets.

Clients

We have partnered with large, fully-integrated textile manufacturers and fashion retailers to create and implement radical solutions which have redefined industry benchmarks. These include: