Consumer Goods & Retail Consulting Services

Organizations producing, distributing, and making products available at retail points can be consumer goods companies or consumer packaged goods companies (CPG). Such companies could develop a constraint in areas like Internal Operations and Distribution, External Distribution, Sales Bandwidth, Retail Operations and New Product Development.

Internal Operations and Distribution

Our Offer

Near

100%

availability of

internal warehouses

Upto

50%

Reduction in

lead time

Upto

25%

Increase in

plants by around

Upto

40%

Reduction in

overall inventories

Improve success rate of new introductions

Eliminate or reduce need for Inventory liquidation sales

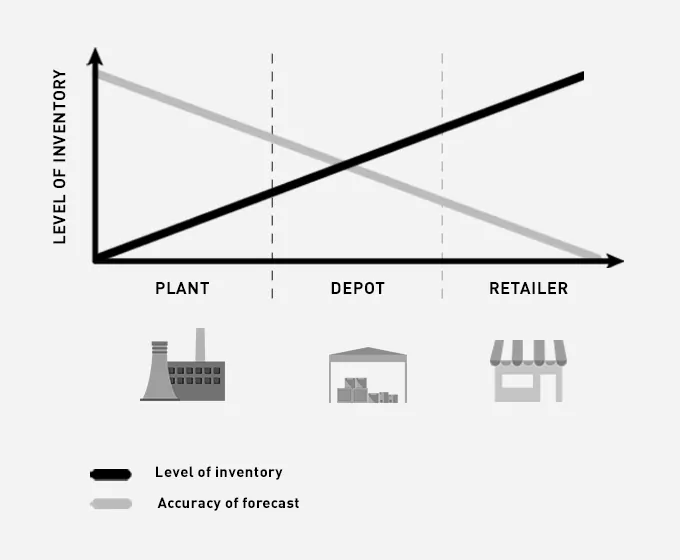

Many consumer goods companies are faced with seemingly contradictory issues in the supply chain. Companies tend to have significant stockouts despite presence of high overall inventory, price pressure from the supply chain intermediaries even though price to the end consumer is unaffected, struggle with new product introductions/product freshness at retail points even as old products clog the pipeline. These problems can be attributed to a single source – incorrect timing of creation and movement of inventory. To resolve this issue, consumer goods manufacturers have tried to improve their forecasting methods and tools. Yet they never get it right. However, the solution to this problem lies in a different direction- in questioning the very need of forecasting.

We offer consulting services to consumer goods and retail companies to help them achieve 100% availability at less than half the inventory in the end-to-end supply chain.

For more information on how consumer goods and retail companies can prevent sales loss by ensuring availability

Read More

External Distribution

Our Offer

Exponentially increase number of retailers covered by direct distribution

More than

100%

Increase in

product available

Sales growth higher than industry average

Near

~100%

availability of relevant range at all billing/retail points

Distributor ROI of close to 60-80% compared to industry benchmarks of only 25-30%

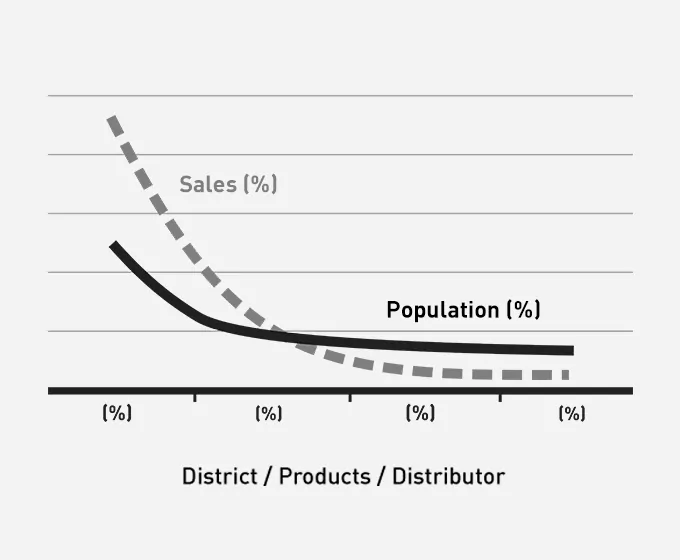

Most consumer goods companies are unable to directly reach all retailers, especially small mom and pop stores and stores that are geographically spread out. To improve reach, such companies usually rely on distributers. However, most distributors tend to cherry-pick retailers in their areas basing their choice on cost of servicing the retailers. They leave out many retailers, unwittingly creating large reach-gaps in many of the companies’ territories. To plug the gap, consumer goods companies then turn to wholesalers. However, wholesalers exacerbate the problem rather than provide real reach. At a loss for ways to strengthen presence in hard-to-reach territories, consumer goods companies often accept the longstanding woe of inadequate reach as ‘unsolvable’.

Vector Consulting helps consumer goods companies to identify highly cost-effective ways of servicing every retail point. Deploying this strategy, companies can strengthen reach with a single-tier distribution network.

Know more about Vector Consulting company’s Go-To-Market strategy that has helped several consumer goods companies to reach out to all potential retailers.

Read More

Sales Bandwidth

Our Offer

More than

50%

Increase in sales capacity

Maximize retail penetration

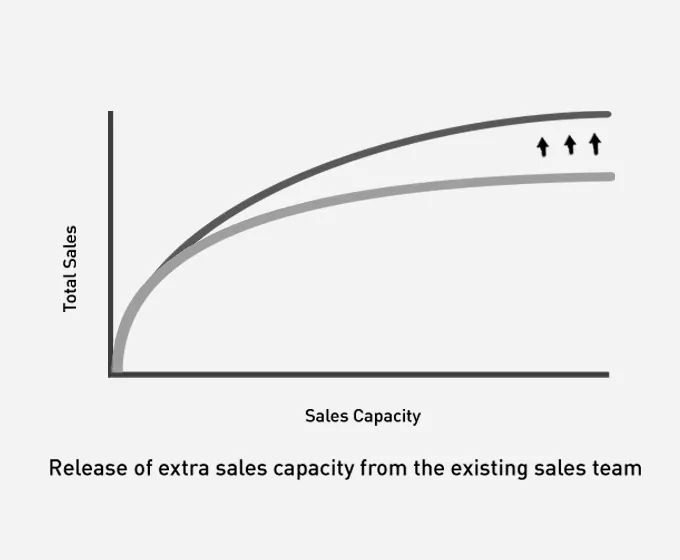

Implementation of TOC systems in internal and external distribution of consumer goods companies, creates a situation where movement of inventory is on auto-pilot. In this new scenario, the sole option by which sales team can increase sales is by focusing on retail points. However, then the load on sales team goes up many folds. The only way to deal with this emergent constraint is to release capacity of sales team and use new methods, structure and processes to effectively identify resolve issues impacting demand at retail points.

To know more about Vector Consulting’s solution for exploiting sales team capacity and to find out how consumer goods companies can profitably reach out to all potential retailers, visit :

Read More

Retail Operations

Our Offer

Around

20%

Growth in same store sales

More than

100%

improvement in inventory turns

Increase gross contribution per unit of retail shelf space

Improve display and freshness of stocks on retail shelf space

Consumer goods companies having their own retail business are typically constrained by shelf-space (or working capital). The speed of inventory rotation on shelf space limits the ability of a retail business to make more money. Shelf space of retail stores is, in many cases, occupied by significant quantity of slow-moving stock. At same time, there is stock out of popular products. Together, the impact is sales loss and poor inventory turns for retail outlets.

We offer consulting services to help our clients in the retail business to significantly increase the rate of sales and, simultaneously, release capital for store expansion.

Companies in the retail business have used Vector Consulting’s end-to-end processes of rapid pull replenishment and rapid replacement to solve the problem of stock outs and slow-moving stocks (without hurting their bottom-line).

Read More

New Product Development

Our Offer

Upto

50%

Reduced project lead time

Upto

50%

Increased output from existing resource base

Reduce rework & improved quality of output

Rapid production stabilization

Improved rate of success of launches

Reduced stress on people and other resources

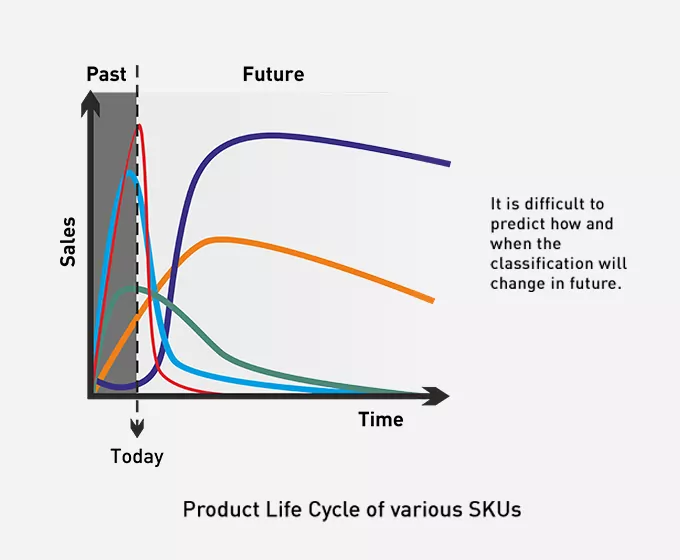

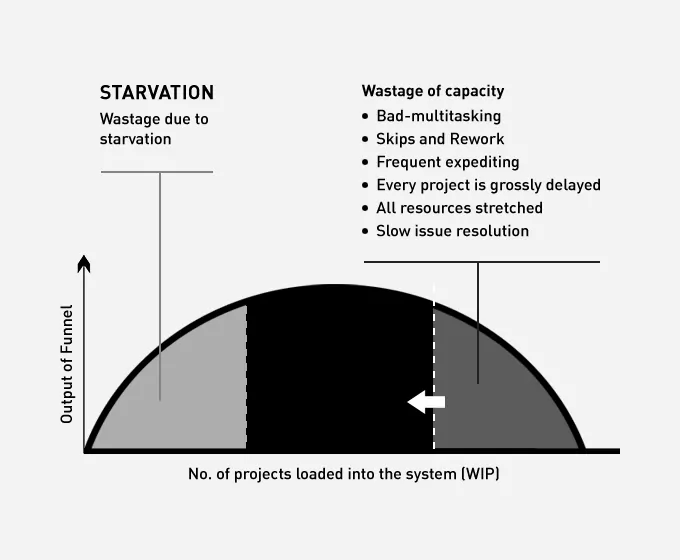

After a consumer goods company acquires a lean and agile distribution and supply chain that is capable of delivering high ROI for trade partners, it can experience the next level of constraint in its ability to launch new products. Companies that make new products are often cluttered with far too many projects; their environments suffer a host of issues such as frequent priority conflicts, rework, delays in production stabilization, and, eventually, delays in launch.

Vector Consulting uses flow principles of TOC to help consumer goods companies increase speed of projects, and, simultaneously, release substantial capacity.

Know more about Vector’s consulting services which enable NPD organizations to permanently cure problems such as chronic delays and low output.

Read More

Case Studies

Vector Consulting Group has transformed numerous supply chains using “pull” systems of Theory of Constraints. Companies like VIP, Bajaj Electricals and others have benefited from Vector’s consulting services which have helped these companies acquire a competitive advantage in their markets.

Clients

We have partnered some of the major names in the consumer goods and retail industry to create and implement radical solutions which have redefined industry benchmarks. These include: