Consulting Services for Engineering and Construction Businesses

An Engineering and Construction (EPC) company’s ability to grow and sustain sales and profits is limited by constraints in Project Management and Sales.

Project Operations

Our Offer

Near

35%

Delivery of EPC projects

Upto

50%

Reduction in working capital deployed

Upto

30%

Release of capacity in departments

Upto

100%

Improvement in profits

Upto

100%

Improved return on capital employed

Upto

50%

Increased sales project delivery sensitive customer segments

EPC organizations that take up turnkey projects (involving engineering, procurement, and site construction) operate in highly uncertain and risky environments. To execute these construction projects, the EPC organizations require co-ordination and co-operation among many stakeholders like state-owned companies, individual landowners contractors, and so on. What’s more, they even may need the weather to be on their side.

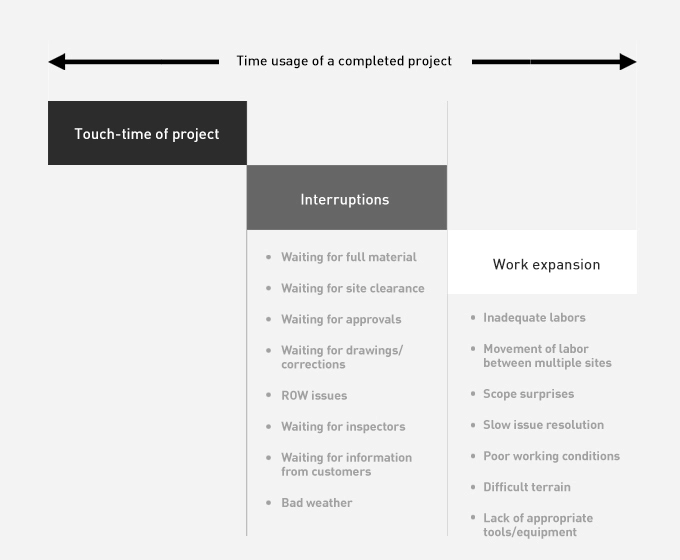

In addition to external uncertainties in an EPC environment, internal aspects such as delay in arrival of designs and staggered arrival of the large variety of material needed for each construction project create de-synchronization. Often, work at the project site is force-started without complete drawings or materials. Frequent interruptions, and inadequate resourcing by contractors add to the delays in EPC projects. Eventually, these construction projects are prematurely commissioned (despite a “tail” of incomplete tasks and billing). These incomplete-but-commissioned projects are unfavourable for both parties. They tie up valued resources of the EPC company. At the same time, customers of these projects have to contend with long periods of low performance (as compared to initial specs).

Most EPC projects in the country suffer chronic delays despite investment in “planning-heavy” solutions and expensive project management software to better manage external and internal uncertainties. This is because none of these project management solutions addresses the key challenge: “How to manage resources and projects DESPITE an environment of high uncertainties.”

Vector Consulting helps EPC companies to deliver projects faster (with shorter lead-times) and within budget and scope. Vector’s solution helps seamlessly align flow of material, design, contract labour, and issue resolution in construction projects. Know more about Vector’s consulting solution:

Read More

Sales

Our Offer

More than

50%

Increase in overall sales

Efficiency to maintain adequate order backlog without dropping prices

Improved quality of customer servicing

Ability to intervene in early stages of the customer ordering process

Stable or improved market share

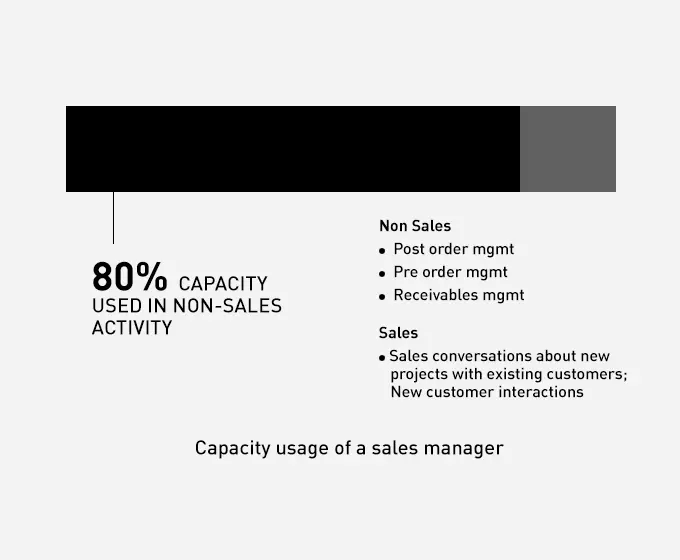

When EPC projects are completed faster, the sales team has to source more project orders (or bid and win more orders) to leverage the released project execution capacity of the company. This is a time-consuming exercise, and often involves engaging with prospective customers at an early stage (even before specs are defined or bids are floated). The sales team’s ability to expand its efforts in the market is restricted when its band-width is taken up by execution, coordination, and documentation-related activities such as design submission, collection coordination, procurement coordination, etc. of existing EPC projects.

With the help of the domain expertise and consulting services of Vector Consulting Group, EPC companies can increase bandwidth and effectiveness of the sales team.

Read More

Diagnostics

The health of Engineering and Construction (EPC) companies is best assessed not by studying their turnover growth but by analyzing the flow rate of projects into the company.

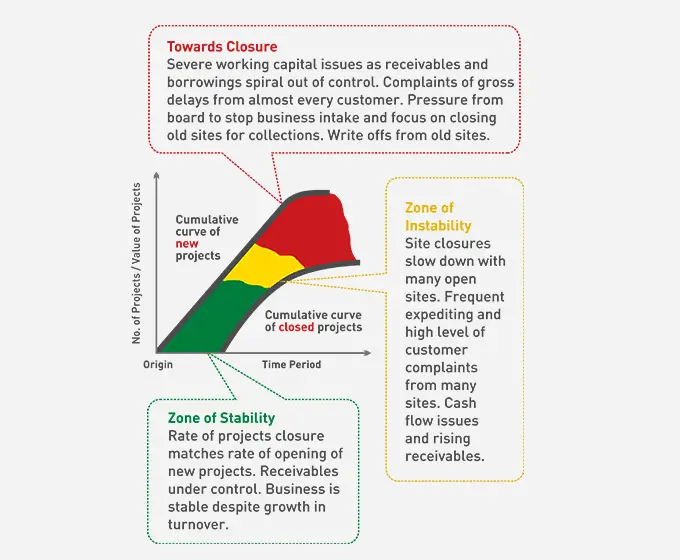

A comparison of the cumulative curve of new project orders in the system and completed projects would reveal that there are three stages in the evolution of an engineering and construction (EPC) company (see graph). In the green stage, an EPC company is able to maintain the rate of project completion in line with the rate of starting new projects. On the other extreme is the red zone in which the EPC company continues to open new projects even as previously opened projects stay incomplete. A project management company approaching the red zone can show turnover growth. However, severe margin losses (during project execution) and ballooning receivables can together restrict entry of new projects (by high margin pricing) and shackle the company’s focus on closing older projects. A standalone small or mid-size EPC company can get wiped out in the red phase!

Conduct a detailed diagnostic on your company with this test designed by Vector Consulting Group to enable EPC companies to evaluate their businesses. You can also get suitable and practical project management solutions.

Case Studies

With the help of Vector’s consulting services, EPC organizations like Bajaj Electricals Ltd, and many others have adopted rapid project execution and management solutions based on Theory of Constraints thinking to transform their project operations.

Clients

We have partnered major names in the EPC industry to create and implement radical solutions which have redefined industry benchmarks. These include: